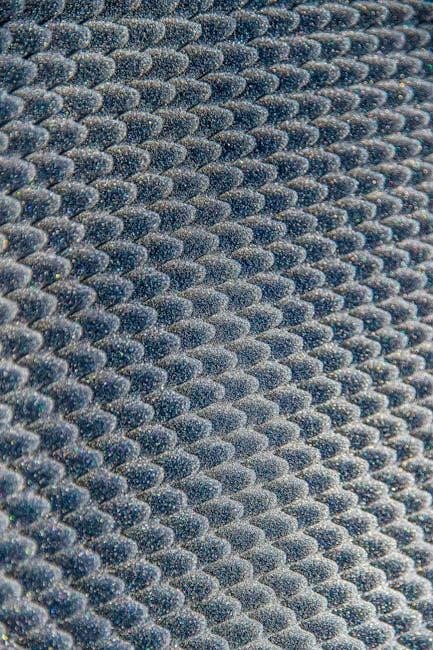

sliding gate guide rollers

Sliding gate guide rollers are essential components that ensure smooth and stable gate movement. They maintain alignment, prevent wobbling, and facilitate effortless operation. Durable and versatile, these rollers are crucial for both residential and industrial gates, ensuring safety and longevity.

1.1 Definition and Purpose

Sliding gate guide rollers are mechanical components designed to facilitate smooth gate movement along a track. Their primary purpose is to maintain alignment, prevent wobbling, and ensure stable operation. Made from materials like nylon or steel, these rollers are essential for both residential and industrial gates, providing durability and reliability while supporting the gate’s weight and promoting safe, efficient functionality.

1.2 Importance in Gate Operation

Guide rollers play a crucial role in ensuring smooth and efficient gate operation. They prevent misalignment and wobbling, reducing wear on the gate and track. By maintaining stability, they enhance safety and extend the lifespan of the gate system. Properly functioning rollers also minimize noise and resistance, making gate operation quieter and more reliable for both manual and automated systems.

Types of Sliding Gate Guide Rollers

Sliding gate guide rollers come in various types, including nylon, steel, and adjustable models. Each offers unique benefits, such as durability, smooth operation, or flexibility in installation.

2.1 Nylon Guide Rollers

Nylon guide rollers are known for their smooth and quiet operation, making them ideal for residential gates. They are durable, resistant to corrosion, and offer excellent wear resistance. These rollers are lightweight, easy to install, and require minimal maintenance. Their ability to glide effortlessly along the track ensures a seamless and noise-free gate movement, enhancing overall user experience and gate longevity.

2.2 Steel Guide Rollers

Steel guide rollers are highly durable and suitable for heavy-duty applications. They offer exceptional strength and resistance to wear and tear, making them ideal for large or industrial gates. Constructed from thick, rust-resistant steel, these rollers provide stability and reliability. Their robust design ensures long-lasting performance, even under harsh conditions, making them a preferred choice for gates requiring maximum support and durability.

2.3 Adjustable Guide Rollers

Adjustable guide rollers offer versatility and flexibility, allowing precise alignment and height adjustments. They are ideal for gates requiring customized setups or uneven tracks. Made from durable materials like nylon or steel, these rollers ensure smooth operation and proper gate alignment. Their adjustability makes them suitable for various gate types and sizes, providing a reliable solution for both residential and industrial applications.

Key Features of High-Quality Guide Rollers

High-quality guide rollers are durable, corrosion-resistant, and designed for smooth, quiet operation. They offer easy installation and maintenance, ensuring reliable performance over time.

3.1 Durability and Resistance to Corrosion

High-quality guide rollers are built to withstand harsh conditions, featuring durable materials like stainless steel or heavy-duty nylon. Their resistance to corrosion ensures longevity, even in moist or outdoor environments. This durability minimizes wear and tear, maintaining smooth gate operation and reducing the need for frequent replacements. Premium options often include protective coatings or rust-resistant treatments for added resilience.

3.2 Smooth and Quiet Operation

Guide rollers with high-quality materials, such as nylon or UHMW plastic, ensure smooth and quiet gate operation. Their sleek design minimizes friction, allowing gates to slide effortlessly; Proper alignment and maintenance further enhance this feature, reducing noise and wear. Heavy-duty options are designed to handle larger loads while maintaining silent movement, making them ideal for both residential and industrial applications.

3.4 Easy Installation and Maintenance

High-quality guide rollers are designed for straightforward installation, often with universal brackets that fit various gate types. Maintenance is minimal, requiring regular cleaning and lubrication to ensure smooth operation. Durable materials like stainless steel and nylon resist corrosion, reducing the need for frequent replacements. Easy adjustment features also allow for fine-tuning, ensuring optimal performance without requiring specialized tools or expertise.

Factors to Consider When Choosing Guide Rollers

When selecting guide rollers, consider load capacity, gate weight, and compatibility with the gate type and track. Environmental conditions and durability are also critical factors to ensure optimal performance and longevity.

4.1 Load Capacity and Gate Weight

Choosing guide rollers with the correct load capacity is crucial to support the gate’s weight effectively. The rollers must be rated for the specific weight of the gate to ensure smooth operation and prevent damage. Exceeding the load capacity can lead to premature wear and potential safety hazards. Always select rollers that match or exceed the gate’s weight requirements for optimal performance and longevity.

4.2 Compatibility with Gate Type and Track

Ensure guide rollers are compatible with your gate type and track system for seamless operation. Different materials, such as nylon or steel, suit various gate weights and track designs. Adjustable rollers offer flexibility for diverse setups, while universal brackets can accommodate multiple track configurations. Proper compatibility ensures smooth movement, reduces friction, and prevents misalignment. Always verify roller specifications match your gate and track system for optimal performance and durability.

4.3 Environmental Conditions

Environmental conditions significantly impact sliding gate guide rollers. Exposure to weather, moisture, and temperature fluctuations can affect durability. In coastal areas, rust-resistant materials like stainless steel are essential. For high-temperature environments, heat-resistant plastics or durable steel rollers are recommended. Additionally, UV protection is crucial for plastic rollers to prevent degradation. Choose rollers suitable for your climate to ensure longevity and reliable performance, avoiding premature wear from environmental stressors.

Installation Best Practices

Proper alignment, secure mounting, and precise adjustments ensure smooth operation. Ensure compatibility with gate type and track, and consider environmental factors like moisture and temperature fluctuations during setup.

5.1 Aligning the Gate and Track

Proper alignment of the gate and track is crucial for smooth operation. Start by leveling the track and ensuring it’s securely fastened. Use a spirit level to check the gate’s position and adjust the rollers as needed. Misalignment can lead to uneven wear, noise, and potential gate failure. Ensure all components are parallel and evenly spaced for optimal performance and longevity.

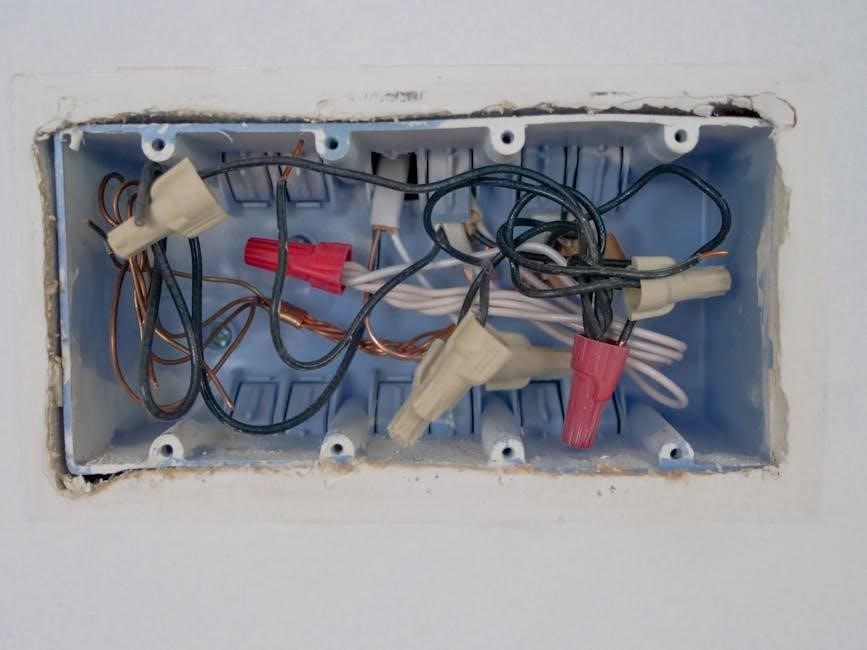

5.2 Securing the Rollers Properly

Securing rollers properly ensures stable gate operation. Use high-quality brackets and bolts, tightening them firmly to avoid movement. Ensure the bracket is level and aligned with the track. Double-check the gate’s movement to confirm smooth operation. Avoid over-tightening, as this may restrict motion. Regularly inspect and tighten bolts to maintain stability and prevent wear. Proper securing enhances durability and performance, ensuring the gate functions safely and efficiently over time.

5.3 Adjusting for Optimal Performance

Adjusting guide rollers ensures smooth gate operation and prevents wear. Align the rollers with the track, using adjustment screws or bolts. Tighten securely but avoid over-tightening, which may restrict movement. Regularly check alignment and make fine adjustments as needed. Proper adjustment enhances stability, reduces noise, and prolongs the lifespan of the gate system. Ensure the gate moves effortlessly along the track for optimal functionality and safety.

Maintenance and Care Tips

Regular cleaning of rollers and tracks ensures smooth operation. Lubricate moving parts periodically to reduce friction and noise. Inspect for wear and tear to prevent issues early.

6.1 Regular Cleaning of Rollers and Track

Regular cleaning of guide rollers and tracks is crucial for maintaining smooth gate operation. Debris, dirt, and grime can accumulate, causing friction and potential damage. Use a soft cloth or brush to remove dust and particles. For tougher grime, apply mild detergents and water, ensuring thorough rinsing to prevent residue buildup. This routine prevents wear and tear, ensuring longevity and reliable performance.

6.2 Lubrication for Smooth Operation

Lubrication is essential for maintaining smooth and quiet operation of sliding gate guide rollers. Apply a high-quality silicone-based spray lubricant to moving parts, ensuring reduced friction and wear. Regular lubrication prevents squeaking and extends the lifespan of the rollers. Avoid using heavy greases that can attract dust and dirt, as they may compromise performance. Proper lubrication guarantees seamless gate movement and minimizes maintenance needs over time.

6.3 Inspecting for Wear and Tear

Regularly inspect sliding gate guide rollers for signs of wear, such as cracks, uneven wear, or excessive play. Check the roller surfaces and axles for damage or corrosion. Ensure the track is free from debris and aligns properly with the rollers. Replace worn-out components promptly to prevent further damage. Consult manufacturer guidelines for recommended inspection schedules and replacement parts to ensure optimal performance and safety.

Common Issues and Troubleshooting

Common issues include noisy operation, misalignment, and roller wear; Troubleshooting involves cleaning debris, adjusting rollers, and replacing worn parts to ensure smooth gate functionality.

7.1 Noisy Operation

Noisy operation in sliding gates is often caused by debris accumulation or lack of lubrication. Regular cleaning of rollers and track, along with proper lubrication, can significantly reduce noise. Worn-out rollers may also contribute, requiring replacement. Ensuring all components are in good condition and well-maintained helps restore quiet operation, enhancing overall gate functionality and longevity.

7.2 Gate Misalignment

Gate misalignment occurs when the gate doesn’t track properly, causing uneven movement. This can result from improper installation, uneven surfaces, or worn guide rollers. Misaligned gates may stick, sway, or fail to close securely. To fix this, check and adjust the rollers, ensuring they align with the track. Proper alignment is crucial for smooth operation and preventing further damage to the gate system.

7.3 Roller Wear and Replacement

Roller wear occurs over time due to friction and heavy use, leading to reduced gate performance. Signs include visible damage, uneven movement, or increased noise. Replacement is necessary when wear compromises functionality. Inspect rollers regularly for cracks or excessive wear. Replace worn rollers with durable alternatives like nylon or steel to restore smooth operation and prevent further damage to the gate system.

Safety Considerations

Ensuring gate stability and preventing accidents are paramount. Regular inspections and proper maintenance of guide rollers are crucial to uphold safety standards and avoid potential hazards.

8.1 Ensuring Gate Stability

Guide rollers play a crucial role in maintaining gate stability by keeping the gate aligned and preventing wobbling. Proper installation and regular maintenance ensure smooth operation and safety. Durable materials like nylon or steel enhance stability, while correct alignment prevents wear and tear. Regular inspections and timely adjustments help avoid potential hazards, ensuring the gate operates securely and reliably over time.

8.2 Preventing Accidents

Guide rollers are vital for preventing accidents by ensuring gates operate smoothly and remain properly aligned. Misaligned or faulty rollers can cause gates to wobble or derail, posing safety risks. Regular inspections, proper installation, and timely maintenance are critical to prevent such hazards. Addressing wear or damage promptly reduces the likelihood of accidents, ensuring a safer environment for users and bystanders alike.

8.3 Compliance with Safety Standards

Compliance with safety standards is crucial for sliding gate systems. Guide rollers must meet specific regulations to ensure reliability and safety. Proper installation, durable materials, and regular inspections help prevent hazards. Adhering to industry standards minimizes risks and ensures gates function as intended. Compliance also involves maintaining proper alignment and functionality, contributing to a safer environment for users and preventing potential accidents caused by malfunctioning components.

Replacement Guide for Worn-Out Rollers

Replacing worn-out rollers ensures smooth gate operation. Inspect for wear, remove old rollers, and install new ones. Choose the right type and size for optimal performance.

9.1 Identifying When to Replace

Identifying when to replace guide rollers is crucial for maintaining gate functionality. Look for signs like excessive noise, visible wear, or misalignment. If rollers show cracks, fractures, or significant material loss, replacement is necessary. Regular inspections can help detect these issues early, preventing gate malfunctions and ensuring smooth operation. Replace rollers promptly to avoid further damage to the gate system.

9.2 Steps for Replacement

Replacing guide rollers involves several key steps. First, ensure the gate is secure and disconnect power. Remove the old rollers by loosening mounting brackets. Install new rollers, ensuring proper alignment and tightening brackets firmly. Adjust for smooth operation and test the gate’s movement. Finally, inspect and clean the track to ensure optimal performance. Proper installation ensures safety and functionality.

9.3 Choosing the Right Replacement Rollers

Selecting the right replacement rollers involves considering compatibility with your gate type and track. Material options like nylon, steel, or UHMW plastic vary in durability and noise reduction. Assess load capacity to match your gate’s weight and ensure proper alignment. Environmental factors, such as exposure to moisture, may require corrosion-resistant models. Prioritize ease of installation and maintenance. Always choose rollers that meet safety standards for reliable performance.

Comparison of Materials

Nylon rollers offer quiet operation and durability, while steel rollers provide strength and rust resistance. UHMW plastic rollers combine high durability with smooth movement, ideal for heavy gates.

10.1 Nylon vs. Steel Rollers

Nylon rollers are known for their smooth, quiet operation and durability, making them ideal for residential gates. Steel rollers, while heavier and more durable, offer superior strength and resistance to rust, suitable for industrial applications. Nylon is quieter but may wear faster under heavy loads, whereas steel provides long-lasting performance but can be noisier. The choice depends on the gate’s weight, usage, and environmental conditions.

10.2 UHMW Plastic Rollers

UHMW (Ultra-High Molecular Weight) plastic rollers are renowned for their exceptional durability and resistance to wear. They offer a low coefficient of friction, ensuring smooth and quiet operation. UHMW rollers are highly resistant to chemicals and temperature variations, making them ideal for harsh environments. Their noise-reducing properties and long lifespan make them a popular choice for heavy-duty gates, providing reliability and minimal maintenance needs over time.

Advanced Features in Modern Guide Rollers

Modern guide rollers feature adjustable offsets, heavy-duty constructions, and integrated safety mechanisms. These advancements enhance performance, durability, and safety, catering to diverse gate systems and operational needs.

11.1 Adjustable Offset Rollers

Adjustable offset rollers offer versatility by allowing precise alignment adjustments. This feature ensures proper gate tracking and minimizes wear. They accommodate varying gate sizes and setups, providing a customized fit. Easy to install and modify, these rollers enhance system adaptability and efficiency, making them ideal for gates requiring frequent adjustments or unique configurations. Their durability ensures long-term performance in diverse environments.

11.2 Heavy-Duty Options

Heavy-duty guide rollers are designed for large and industrial gates, offering exceptional strength and durability. Constructed from robust materials like steel or high-grade nylon, they withstand heavy loads and harsh conditions. These rollers feature reinforced brackets and advanced corrosion resistance, ensuring smooth operation under stress. Ideal for commercial settings, they provide reliability and longevity, making them a practical choice for demanding applications.

11.3 Integrated Safety Mechanisms

Modern guide rollers often feature integrated safety mechanisms to prevent accidents and ensure secure operation. These include sensors to detect obstacles, emergency stop systems, and secure locking features. They comply with safety standards, enhancing gate stability and preventing unintended movement. Such mechanisms are vital for automated gates, offering peace of mind and protecting users from potential hazards.

The Future of Sliding Gate Guide Rollers

The future of sliding gate guide rollers lies in innovative materials and smart solutions, enhancing durability, efficiency, and automation for safer and smoother gate operations.

12.1 Innovations in Material Technology

Innovations in material technology are revolutionizing sliding gate guide rollers, with advancements in UHMW plastic and high-strength nylon offering enhanced durability and resistance to wear. Modern materials like stainless steel and rust-proof coatings improve longevity in harsh environments. These developments ensure smoother operation, reduced maintenance, and compatibility with various gate systems, catering to both residential and industrial needs while meeting sustainability standards.

12.2 Smart and Automated Solutions

Smart and automated solutions are transforming sliding gate guide rollers, integrating advanced technologies like sensors and IoT connectivity. These innovations enable real-time monitoring, automated adjustments, and seamless integration with smart home systems. Automated rollers can detect obstacles, adjust alignment, and optimize performance, enhancing safety and efficiency. Such solutions also reduce manual intervention, ensuring gates operate smoothly while adapting to environmental changes, making them ideal for modern, tech-savvy applications.

Sliding gate guide rollers are vital for ensuring smooth, stable, and efficient gate operation. By understanding their types, features, and maintenance requirements, users can optimize performance and longevity. Proper selection, installation, and care are crucial for safety and functionality. As technology advances, innovative solutions like smart and automated rollers promise enhanced convenience and reliability, making them a worthwhile investment for modern gating systems.