cessna 172n parts manual

Cessna 172N Parts Manual: A Comprehensive Overview

This overview details essential resources for Cessna 172N maintenance, including official catalogs like P696-12 and illustrated parts catalogs.

These manuals cover every component, aiding in accurate identification and procurement of necessary replacements.

The Cessna 172N Skyhawk, a cornerstone of general aviation, demands meticulous maintenance facilitated by comprehensive parts documentation. Understanding the intricacies of the 172N requires access to detailed parts manuals, ensuring safe and efficient operation.

These manuals, such as the Cessna 172 Series Parts Catalog, are vital for identifying components, understanding assembly, and sourcing replacements. They range from covering interior plastics to complex airframe structures. Proper utilization of these resources is paramount for aircraft owners, mechanics, and aviation enthusiasts alike, guaranteeing continued airworthiness and performance.

Understanding Parts Manuals for Aircraft Maintenance

Aircraft parts manuals are critical for safe and compliant maintenance, providing detailed illustrations and part numbers essential for accurate repairs and replacements. These catalogs, like the Cessna P696-12, supersede older versions, ensuring technicians have the most current information.

Understanding nomenclature and interpreting diagrams are key skills. Manuals detail everything from rivets to elevators, aiding in precise component identification. Utilizing these resources minimizes errors, promotes airworthiness, and supports regulatory compliance, ultimately safeguarding flight operations and passenger safety.

Locating Cessna 172N Parts Manuals

Finding the correct manual involves exploring official Cessna catalogs (P696-12), third-party illustrated options, and leveraging digital databases for comprehensive parts information.

Official Cessna Parts Catalogs (P696-12)

Cessna’s official P696-12 parts catalog is the definitive resource for 172N maintenance. It meticulously details every component, superseding earlier catalogs dated before February 1968.

This catalog provides accurate part numbers, illustrations, and crucial information for identifying and ordering replacements.

It’s a substantial volume, containing 490 pages filled with detailed diagrams.

Accessing this catalog ensures compatibility and adherence to Cessna’s specifications, vital for safe and effective aircraft upkeep.

Authorized dealers are primary sources for obtaining this essential manual.

Third-Party Illustrated Parts Catalogs

Beyond Cessna’s official offerings, several third-party illustrated parts catalogs exist for the 172N. These catalogs often present information in a user-friendly format, supplementing the P696-12.

They can be valuable for cross-referencing part numbers and visualizing component assemblies.

However, it’s crucial to verify the accuracy and applicability of information from these sources against official Cessna documentation.

While convenient, third-party catalogs should not replace the authoritative P696-12 for critical maintenance decisions, ensuring proper part selection and aircraft safety.

Digital Resources and Online Databases

Numerous digital resources and online databases assist in locating Cessna 172N parts and related information. These platforms often host scanned copies of parts catalogs, including the P696-12, and offer searchable databases of parts numbers.

Online marketplaces and aviation-specific forums can also be valuable for sourcing parts and connecting with other owners and mechanics.

However, always exercise caution when purchasing parts online, verifying the seller’s reputation and the part’s condition before completing a transaction.

Key Components Covered in the Manual

The Cessna 172N parts manual meticulously details airframe structures, engine systems, landing gear, avionics, and electrical components, ensuring comprehensive maintenance support.

Airframe Structure and Components

The manual provides exhaustive details regarding the Cessna 172N’s airframe, encompassing everything from the fuselage and wings to control surfaces like elevators, ailerons, and the rudder.

Detailed illustrations and part numbers facilitate accurate identification of structural elements, including rivets, screws, and larger components.

It covers skin panels, fairings, and internal support structures, crucial for maintaining the aircraft’s integrity.

The catalog supersedes previous versions dating back to 1962, ensuring up-to-date information for mechanics and owners.

Proper identification is key for safe and effective repairs.

Engine and Related Systems

The Cessna 172N parts manual meticulously details the engine and its associated systems, offering comprehensive breakdowns of components. This includes the carburetor, fuel system, ignition, and exhaust.

Illustrated parts catalogs provide clear diagrams for identifying each part, ensuring correct replacements during maintenance or repairs.

Specific part numbers and nomenclature are crucial for ordering, and the manual aids in accurate identification.

Access to these details is vital for maintaining engine performance and adhering to safety regulations.

Detailed schematics support troubleshooting and overhaul procedures.

Landing Gear Systems

The Cessna 172N parts manual provides exhaustive details of the landing gear systems, encompassing the main landing gear, nose gear, wheels, brakes, and associated hardware.

Illustrated parts catalogs offer detailed diagrams for identifying each component, facilitating accurate maintenance and repair procedures.

Correct part numbers and nomenclature are essential for safe operation, and the manual ensures precise ordering of replacements.

This section covers everything from tires and tubes to brake lines and cylinders, supporting thorough inspections and overhauls.

Avionics and Electrical Systems

The Cessna 172N parts manual meticulously details the avionics and electrical systems, covering wiring harnesses, circuit breakers, switches, and instruments.

Illustrated parts catalogs provide clear diagrams for identifying each component, crucial for troubleshooting and repair.

Accurate part numbers are vital for maintaining system integrity, ensuring compatibility and safe operation.

The manual supports comprehensive inspections, replacements, and upgrades of radios, navigation equipment, and electrical components, adhering to aviation standards.

Navigating the Parts Manual

Understanding part numbers, nomenclature, and illustrations is key. The manual’s diagrams and serial number applicability ensure correct component identification for your Cessna 172N.

Understanding Part Numbers and Nomenclature

Decoding Cessna part numbers is crucial for accurate ordering. These numbers aren’t simply random; they contain information about the part’s function, material, and applicable aircraft models. Nomenclature, or the naming convention, follows a logical system. For example, a “retainer” is a specific type of fastener.

Illustrated parts catalogs detail these numbers alongside diagrams. Knowing the correct terminology prevents misunderstandings when communicating with parts suppliers. Furthermore, understanding the catalog’s structure allows for efficient searching and identification of the precise component needed for your Cessna 172N’s maintenance or repair.

Interpreting Illustrations and Diagrams

Cessna parts manuals heavily rely on detailed illustrations and diagrams. These aren’t merely visual aids; they’re integral to identifying components and understanding their assembly. Each part is typically numbered, corresponding directly to the parts list. Exploded views showcase how parts fit together, simplifying maintenance procedures.

Pay close attention to shading and line styles, as these often indicate different materials or manufacturing processes. Mastering the interpretation of these visuals is essential for successful aircraft maintenance, ensuring correct part placement and preventing errors during repairs or inspections.

Serial Number Applicability

Cessna 172N parts manuals aren’t universally applicable across all aircraft. Variations existed during the production run, necessitating careful attention to serial number applicability. Manuals clearly define the serial number ranges for which specific parts and diagrams are valid. For example, parts listed for 172N serials 17272885-17275034 may differ from those used on earlier or later models.

Always verify that the manual’s serial number range encompasses your aircraft’s serial number before ordering or installing any parts. Ignoring this crucial step can lead to incompatibility and potentially compromise flight safety.

Specific Parts and Common Replacements

Common replacements include interior plastics, headliners, and exterior panels. Control surfaces like elevators, ailerons, and rudders also frequently require attention and parts.

Interior Parts (Headliners, Plastics)

The Cessna 172N’s interior relies on specific plastic components and headliners prone to wear and tear. Replacements for these parts, like retainers for headliners (FAA-PMA pending P0515024-8), are readily available.

These components often require replacement due to sun exposure, age, or accidental damage. Identifying the correct part number is crucial, and illustrated parts catalogs are invaluable for this process. Serial number applicability must be verified to ensure compatibility with the specific aircraft. Maintaining a well-kept interior enhances both comfort and resale value.

Exterior Parts (Panels, Fairings)

Cessna 172N exterior parts, including panels and fairings, are susceptible to damage from environmental factors and flight operations. Accessing detailed parts catalogs, such as P696-12, is essential for identifying and ordering replacements.

These catalogs provide illustrations and part numbers for various exterior components. Proper identification, considering the aircraft’s serial number, is vital for ensuring a correct fit. Maintaining the exterior not only preserves the aircraft’s appearance but also contributes to its aerodynamic efficiency and structural integrity.

Control Surfaces (Elevators, Ailerons, Rudder)

The Cessna 172N’s control surfaces – elevators, ailerons, and rudder – are critical for flight control and require meticulous maintenance. Illustrated parts catalogs, like the comprehensive P696-12, are invaluable for identifying each component.

These manuals detail everything from hinges and balance weights to the surfaces themselves. Accurate part numbers, cross-referenced with the aircraft’s serial number, are essential for safe and effective repairs. Maintaining these surfaces ensures optimal flight performance and pilot safety, demanding precise replacements.

FAA-PMA Approved Parts

FAA-PMA parts offer approved alternatives for Cessna 172N repairs, ensuring safety and regulatory compliance. Catalogs indicate parts with pending or approved PMA status.

Understanding FAA-PMA

FAA-PMA, or Federal Aviation Administration – Parts Manufacturer Approval, is a crucial process allowing manufacturers to produce replacement parts for aircraft. These parts must meet rigorous quality and performance standards equivalent to the original equipment manufacturer (OEM) parts.

Utilizing FAA-PMA approved parts provides a cost-effective alternative to OEM components while maintaining airworthiness. The approval signifies the part’s design and manufacturing processes have been vetted by the FAA.

For the Cessna 172N, identifying FAA-PMA parts within catalogs is vital for maintenance professionals and owners seeking compliant and reliable replacements. Look for specific designations within parts listings.

Locating FAA-PMA Parts for Cessna 172N

Finding FAA-PMA approved parts for your Cessna 172N requires diligent searching. Aircraft parts suppliers often specialize in these alternatives, clearly marking them within their catalogs and online databases. Look for the FAA-PMA designation alongside the part number.

Specifically, examples like a retainer-headliner (P0515024-8) demonstrate FAA-PMA applicability for certain 172N components. Authorized Cessna dealers may also offer FAA-PMA options. Online marketplaces can be useful, but verify the supplier’s credentials and the part’s approval status.

Historical Parts Catalogs

Older catalogs, like those from 1956-1962 and 1977-1981, provide valuable insight for restoration projects and understanding component evolution within the Cessna 172 series.

Cessna 172/175 Parts Catalog (1956-1962)

The Cessna 172/175 Parts Catalog, covering models from 1956 to 1962, is a foundational resource for early Skyhawk maintenance. Priced at $245.00, this catalog details components specific to those initial production years.

It’s crucial for owners restoring or maintaining these classic aircraft, offering detailed illustrations and part numbers. Notably, this catalog is non-returnable, emphasizing its archival and specialized nature. Applicability is strictly limited to the 1956-1962 Cessna 172 and 175 models, providing a focused resource for owners and mechanics alike.

Cessna R172 Parts Catalog (1977-1981)

The Cessna R172 Parts Catalog, specifically for models manufactured between 1977 and 1981, is an essential maintenance document. Currently priced at $202.07, this catalog provides detailed breakdowns of components unique to the R172 variant.

It aids in accurate identification and sourcing of replacement parts for these aircraft. Like the earlier catalog, returns are not accepted, highlighting its specialized nature. This catalog’s applicability is limited to the 1977-1981 Cessna R172, serving as a focused resource for owners and aviation technicians.

Resources for Parts Procurement

Parts can be sourced from Cessna authorized dealers, specialized aircraft parts suppliers, and various online marketplaces offering both new and used components;

Cessna Authorized Dealers

Cessna Authorized Dealers represent a primary source for genuine Cessna 172N parts, ensuring quality and adherence to manufacturer specifications. These dealers possess direct access to the latest parts catalogs, including the comprehensive P696-12, and can provide expert guidance on component selection.

They offer a reliable supply chain, minimizing the risk of encountering non-approved or substandard replacements. While often representing a higher initial cost, utilizing authorized dealers guarantees compatibility and supports continued airworthiness. Dealers can also assist with locating FAA-PMA approved alternatives when applicable, offering a balanced approach to parts procurement.

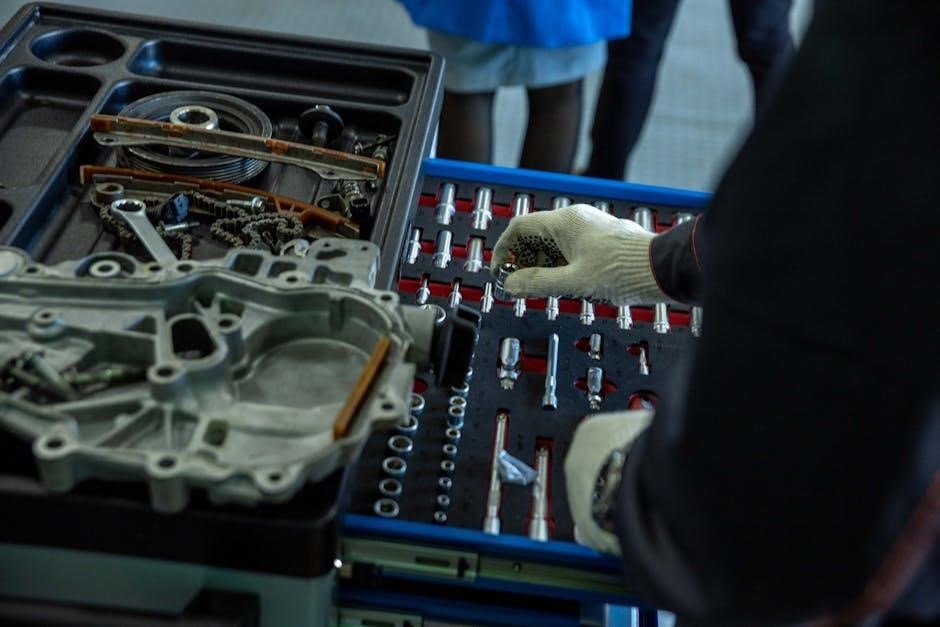

Aircraft Parts Suppliers

Numerous aircraft parts suppliers specialize in Cessna components, offering a broader range of options beyond authorized dealers. These suppliers often stock both new and used parts, potentially providing cost savings for Cessna 172N maintenance. However, diligent verification of part quality and traceability is crucial.

Suppliers may offer access to illustrated parts catalogs and assist in identifying correct components. It’s essential to confirm FAA-PMA approval where applicable and ensure parts meet airworthiness standards. Thorough research and vetting of suppliers are paramount for safe and compliant aircraft operation.

Online Marketplaces

Online marketplaces present another avenue for sourcing Cessna 172N parts, offering a diverse selection from various sellers. However, exercising extreme caution is vital when utilizing these platforms. Part traceability and airworthiness documentation can be challenging to verify, increasing the risk of acquiring unapproved or substandard components.

Thorough seller vetting, detailed part inspection upon receipt, and confirmation of FAA-PMA approvals are essential. While potentially offering competitive pricing, online marketplaces demand heightened due diligence to ensure safety and regulatory compliance during aircraft maintenance.

Maintaining Your Cessna 172N

Proper maintenance hinges on utilizing correct parts, detailed record-keeping, and regular inspections as outlined in the Cessna 172N parts manual.

Importance of Using Correct Parts

Employing the correct parts is paramount for the continued airworthiness and safety of your Cessna 172N. Utilizing incorrect or unapproved components can compromise structural integrity, system functionality, and overall aircraft performance.

The Cessna 172N parts manual serves as the definitive guide for identifying the precise part numbers and specifications required for each component. Adhering to these specifications ensures compatibility and prevents potential failures. FAA-PMA approved parts offer a viable alternative, maintaining safety standards.

Incorrect parts can lead to costly repairs, reduced aircraft value, and, most critically, jeopardize flight safety. Always consult the manual and authorized dealers for accurate part selection.

Regular Inspection and Maintenance

Consistent inspection and maintenance, guided by the Cessna 172N parts manual, are crucial for longevity and safety. Scheduled checks reveal wear and tear, enabling proactive part replacement before failures occur. The manual details component locations and proper procedures.

Focus on areas identified in the manual as prone to wear, like interior plastics and control surfaces. Utilizing the correct parts, as specified, ensures repairs maintain original performance standards.

Diligent maintenance, coupled with accurate parts referencing, minimizes downtime and maximizes the aircraft’s operational lifespan. Prioritize safety through routine checks and timely replacements.

Record Keeping and Documentation

Meticulous record-keeping is paramount when maintaining a Cessna 172N, directly linked to utilizing the parts manual effectively. Document all inspections, maintenance performed, and parts replaced, referencing specific part numbers from the manual.

This creates a traceable history, vital for FAA compliance and future maintenance. Accurate records demonstrate adherence to safety standards and aid in troubleshooting.

Detailed documentation, including serial numbers and dates, ensures accountability and facilitates efficient parts procurement. Maintaining a comprehensive logbook enhances the aircraft’s value and operational reliability.