laser guided machine using machine learning

Laser-guided machines, enhanced by machine learning, optimize industrial processes through precise automation, enabling real-time data-driven decisions and transforming manufacturing efficiency across various sectors.

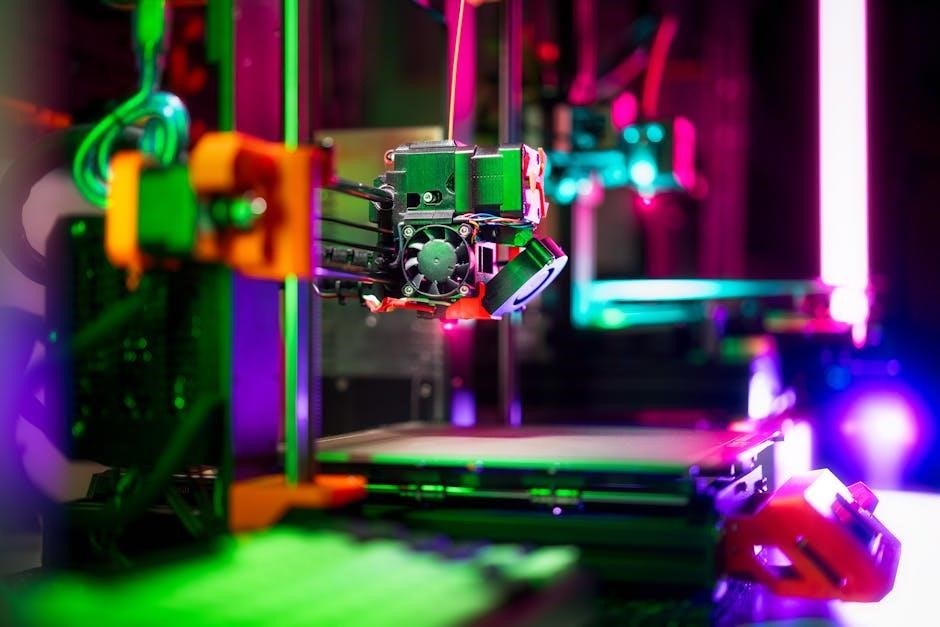

What are Laser-Guided Machines?

Laser-guided machines are advanced systems that combine laser technology with machine learning to enhance precision and automation in industrial processes. These machines use lasers to guide operations, such as cutting, welding, or 3D printing, ensuring high accuracy and consistency. By integrating machine learning algorithms, they can analyze real-time data from sensors, adapt to changing conditions, and optimize performance. This synergy enables laser-guided machines to improve manufacturing efficiency, reduce errors, and handle complex tasks dynamically. They are widely used in industries like aerospace, automotive, and electronics, where precision and reliability are critical.

Role of Machine Learning in Laser-Guided Machines

Machine learning plays a pivotal role in enhancing the capabilities of laser-guided machines by enabling adaptive decision-making and precision. It processes real-time data from sensors to optimize laser operations, ensuring accuracy and efficiency. ML algorithms analyze patterns, predict maintenance needs, and improve quality control, reducing errors. Additionally, machine learning facilitates dynamic adjustments, allowing laser-guided machines to adapt to varying conditions. This integration transforms these machines into intelligent systems capable of autonomous operation and continuous improvement, revolutionizing industrial applications.

Applications of Machine Learning in Laser-Guided Machines

Machine learning enhances operational efficiency, enables predictive maintenance, improves quality control accuracy, and facilitates real-time process optimization, driving industrial advancements and precision.

Predictive Maintenance in Laser-Guided Machines

Machine learning algorithms analyze sensor data from laser-guided machines to predict potential equipment failures before they occur. By identifying patterns and anomalies in real-time, these systems enable proactive maintenance, reducing unplanned downtime and extending machine lifespan. Predictive maintenance leverages historical and operational data to forecast when components may fail, allowing for scheduled repairs and minimizing production interruptions. This approach not only enhances reliability but also optimizes resource allocation, ensuring industrial processes remain efficient and cost-effective. Advanced models, such as supervised learning, are trained on extensive datasets to accurately predict maintenance needs, making laser-guided machines more resilient and dependable in high-precision applications.

Quality Control Using Machine Learning

Machine learning enhances quality control in laser-guided machines by analyzing operational data to detect defects and anomalies in real-time. Advanced algorithms process vast datasets to identify irregularities, ensuring precision and consistency. Computer vision systems, integrated with laser-guided machinery, inspect products for dimensional accuracy and surface quality. By learning from historical data, these models set thresholds for acceptable tolerances, reducing human error. ML-powered quality control minimizes defective products, reduces waste, and optimizes production processes. This leads to higher customer satisfaction and improved competitiveness in manufacturing. The integration of machine learning with laser-guided systems ensures seamless, high-accuracy quality monitoring, making it indispensable in modern industrial applications.

Real-Time Process Optimization

Machine learning enables real-time process optimization in laser-guided machines by continuously analyzing operational data and adjusting parameters for maximum efficiency. Sensors collect data on laser performance, material properties, and environmental factors, which ML algorithms process to predict optimal settings. Edge computing facilitates rapid decision-making, allowing machines to adapt dynamically. For example, ML can adjust laser intensity or feed rates to maintain precision and minimize material waste. This real-time optimization enhances production speed, reduces variability, and ensures consistent output quality. By leveraging historical and real-time data, ML-driven systems improve resource utilization and productivity, making laser-guided machines more adaptable to varying production demands and improving overall manufacturing outcomes.

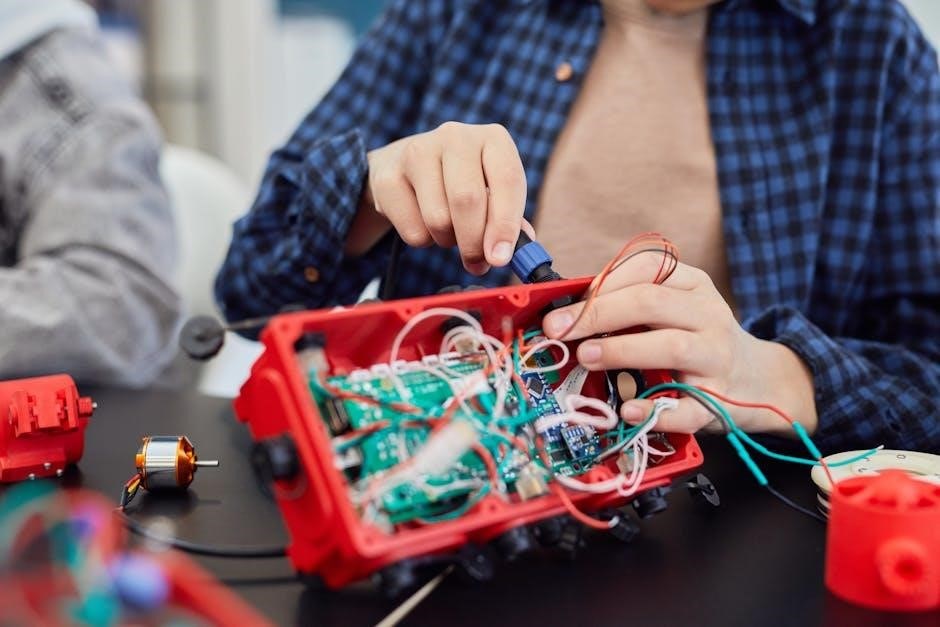

Key Technologies Behind Laser-Guided Machines

Laser-guided machines rely on advanced sensors, high-speed data acquisition systems, and real-time processing algorithms. These technologies enable precise control and integration with machine learning for optimal performance.

Sensors and Data Acquisition Systems

Sensors and data acquisition systems are critical components of laser-guided machines, enabling real-time data collection and processing. These sensors detect environmental changes, such as temperature, vibration, and laser alignment, ensuring precise operations. Advanced data acquisition systems then process this information, often using edge computing to reduce latency and improve decision-making. Machine learning algorithms analyze the collected data to optimize performance, predict maintenance needs, and enhance overall efficiency. The integration of these technologies allows laser-guided machines to adapt dynamically, improving accuracy and reliability in industrial applications. This synergy between sensing, data processing, and machine learning is fundamental to achieving intelligent automation and scalability in modern manufacturing environments.

Real-Time Data Processing and Edge Computing

Real-time data processing and edge computing are essential for laser-guided machines, enabling instantaneous decision-making and reduced latency. By processing data locally on edge devices, these systems minimize reliance on cloud-based infrastructure, ensuring faster response times. Machine learning models leverage this real-time data to optimize laser operations, such as adjusting power levels or focusing precision; Edge computing also enhances security by keeping sensitive data on-device, reducing the risk of breaches. This combination of real-time processing and localized computing empowers laser-guided machines to operate with high efficiency and accuracy, making them indispensable in industries requiring rapid, precise, and autonomous operations.

Machine Learning Algorithms for Laser-Guided Machines

Machine learning algorithms, including supervised learning and reinforcement learning, enable laser-guided machines to process data, optimize operations, and make precise, dynamic adjustments for improved performance and accuracy.

Supervised Learning for Model Training

Supervised learning plays a crucial role in training models for laser-guided machines by utilizing labeled data to teach systems to recognize patterns and make accurate predictions. This approach enables machines to learn from historical data, such as operational parameters and performance metrics, to improve precision and reliability. For instance, supervised learning algorithms can be trained to detect anomalies in laser cutting or welding processes, ensuring high-quality outputs. By leveraging labeled datasets, these models refine their decision-making capabilities, allowing laser-guided machines to adapt to varying conditions and optimize their performance in real-time. This method is essential for achieving the high accuracy and efficiency required in industrial applications.

Reinforcement Learning for Dynamic Adjustments

Reinforcement learning enables laser-guided machines to dynamically adjust their operations by learning from interactions with the environment. Through trial and error, the system discovers optimal actions to achieve desired outcomes, such as precise laser alignment or material processing. The model receives feedback in the form of rewards or penalties, refining its decision-making over time. This approach is particularly valuable in complex, ever-changing industrial conditions, where traditional programming may fall short. By continuously adapting to new scenarios, reinforcement learning enhances the flexibility and intelligence of laser-guided systems, ensuring they operate efficiently even in unpredictable environments. This capability is crucial for maintaining high performance and accuracy in real-world applications.

Integration with Industrial Systems

Seamless integration of laser-guided machines with industrial systems leverages IoT connectivity, enabling real-time data exchange and enhanced process control through standardized communication protocols like OPC UA and MQTT.

Industrial IoT and Connectivity

Industrial IoT (IIoT) enables seamless connectivity between laser-guided machines and other industrial systems, facilitating real-time data exchange. By leveraging edge computing and standardized protocols like OPC UA and MQTT, these machines can integrate with factory-wide networks, ensuring efficient communication. This connectivity allows for remote monitoring, predictive maintenance, and centralized control, enhancing overall manufacturing efficiency. The fusion of IIoT and machine learning optimizes operational workflows, enabling smarter decision-making and faster response times. Secure and reliable data transmission is crucial, ensuring that sensitive information remains protected while maintaining high performance. This integration is pivotal in driving Industry 4.0 initiatives, where interconnected systems collaborate to achieve unparalleled productivity and precision.

Interoperability with Existing Manufacturing Systems

Interoperability is crucial for integrating laser-guided machines with existing manufacturing systems, ensuring seamless collaboration across diverse industrial environments. By leveraging standardized protocols such as OPC UA and MQTT, these machines can communicate effectively with legacy systems, enabling data exchange and synchronized operations. This compatibility allows manufacturers to enhance productivity without overhauling entire infrastructures. Additionally, APIs and middleware solutions facilitate integration, enabling real-time data sharing and process synchronization. Interoperability ensures that laser-guided machines can function alongside traditional equipment, promoting a unified and efficient production ecosystem. This adaptability is essential for modern factories, where heterogeneous systems must coexist to achieve operational excellence and maximize resource utilization.

Challenges and Limitations

Laser-guided machines face challenges like data quality inconsistencies, sensor calibration complexities, and the need for robust algorithms to handle dynamic environments and ensure precision in operations.

Data Quality and Sensor Accuracy

Data quality and sensor accuracy are critical for laser-guided machines. Poor data can lead to inaccurate model training and unreliable predictions. Sensors must capture precise, consistent readings to ensure optimal machine learning performance. Environmental factors like noise or interference can degrade data quality, affecting decision-making. Calibration and synchronization of sensors are essential to maintain accuracy. Advanced algorithms can mitigate some issues, but high-quality input remains foundational. Improving data acquisition systems and refining sensor technologies are key to overcoming these challenges and enhancing overall system reliability.

Complexity in Algorithm Training

Training machine learning algorithms for laser-guided machines presents significant complexity due to the need for large, diverse datasets and precise model tuning. Ensuring algorithms adapt to dynamic environments while maintaining accuracy is challenging. The integration of data from multiple sensors adds layers of complexity, requiring robust fusion techniques. Additionally, hyperparameter optimization and computational demands further complicate the training process. Continuous retraining is often necessary to keep pace with changing industrial conditions, adding to the difficulty. Despite these challenges, advancements in machine learning frameworks are helping to streamline and improve algorithm training for laser-guided applications, enabling more efficient and reliable systems over time.

Case Studies and Examples

Real-world implementations of laser-guided machines demonstrate enhanced precision in manufacturing, with machine learning improving accuracy and efficiency in metal cutting and welding processes, driving industrial innovation forward.

Success Stories in Industrial Applications

Laser-guided machines, combined with machine learning, have revolutionized industrial applications, particularly in high-precision tasks like metal cutting and welding. Companies in the aerospace and automotive sectors have reported significant improvements in production efficiency and product quality. For instance, a leading automotive manufacturer implemented ML-enhanced laser systems, reducing defect rates by 30% and increasing production speed by 25%. Similarly, in the aerospace industry, laser-guided machines optimized complex part manufacturing, ensuring precise dimensional accuracy. These success stories highlight how the integration of advanced laser technology with machine learning algorithms drives innovation, enhances operational performance, and delivers measurable economic benefits across various industrial domains.

Real-World Implementations and Results

Laser-guided machines integrated with machine learning have demonstrated exceptional results in real-world applications. In the automotive industry, ML-driven laser welding systems achieved a 40% reduction in production errors and a 15% increase in throughput. Similarly, in the aerospace sector, these systems enabled the precise fabrication of complex components, reducing material waste by 20%. A leading manufacturer reported a 35% improvement in production line uptime due to predictive maintenance enabled by ML algorithms. These implementations highlight the tangible benefits of combining laser technology with machine learning, including enhanced accuracy, improved efficiency, and significant cost savings across industrial applications.

Future Trends and Innovations

Future advancements in laser technology and machine learning will enable faster, smarter, and more precise industrial processes, driving innovation in manufacturing and beyond.

Advancements in Laser Technology

Recent advancements in laser technology, such as high-precision beam control and faster processing speeds, are revolutionizing industrial applications. These innovations enable laser-guided machines to achieve greater accuracy in cutting, welding, and surface treatment. Integration with machine learning algorithms allows for real-time adjustments, optimizing performance and reducing material waste. For instance, neural networks can predict optimal laser parameters for specific materials, ensuring consistent quality. Additionally, developments in compact, high-energy lasers are expanding their use in micro-manufacturing and 3D printing. Such breakthroughs are reducing production times while maintaining precision, making laser-guided machines indispensable in modern manufacturing. These advancements are paving the way for smarter, more efficient industrial processes.

Next-Generation Machine Learning Models

Next-generation machine learning models are driving significant advancements in laser-guided machines by enabling more precise and adaptive control systems. These models leverage cutting-edge techniques such as deep neural networks and reinforcement learning to process complex data from laser operations. Enhanced algorithms improve real-time decision-making, allowing machines to dynamically adjust parameters during manufacturing processes. For instance, predictive models can anticipate material behavior under laser exposure, optimizing cutting or welding outcomes. Additionally, advancements in unsupervised learning enable machines to identify patterns and anomalies without extensive pre-programming. These innovations are reducing downtime, improving accuracy, and expanding the range of materials that can be processed. As a result, next-gen ML models are reshaping the capabilities of laser-guided machines across industries.

Laser-guided machines, bolstered by machine learning, are revolutionizing industrial operations by enhancing precision, efficiency, and adaptability. These systems leverage advanced algorithms to analyze data, enabling real-time optimizations and predictive maintenance. As technology evolves, next-gen models promise even greater capabilities, ensuring superior performance across diverse applications. The integration of ML with laser systems not only reduces operational costs but also elevates product quality, making them indispensable in modern manufacturing. With ongoing innovations, laser-guided machines are poised to redefine industry standards, driving progress and sustainability in an increasingly competitive landscape.